The oil permeability of the coil substrate has been greatly improved, and the coil substrate has no flowing or dripping, which is currently impossible for any material on the market to achieve。

There is a significant improvement in the quality increase of the coil after immersion, at around 0.3%. Suggest a ratio of SMA to asphalt of 4:6 or 5:5 (the softening point of asphalt after 4:6 mixing is around 70 ℃, and the softening point of asphalt after 5:5 mixing is around 80 ℃)

Due to the presence of modifiers such as silicone in SMA, it has an improvement effect on the high and low temperature of the surface layer of the coil, while traditional pre impregnation methods can cause damage to the surface layer. (At around -20 ℃ at 5:5)

Improved the porosity issue on the surface of the coil, enhanced its standing, and made the coil more upscale。

With current technologies (such as encrypted and thickened tire bases), it is difficult to achieve 500N for pre laid roll materials. After adding SMA pre impregnated materials, ordinary tire bases can reach nearly 700N。

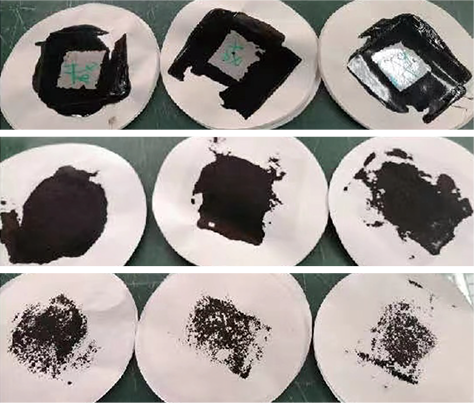

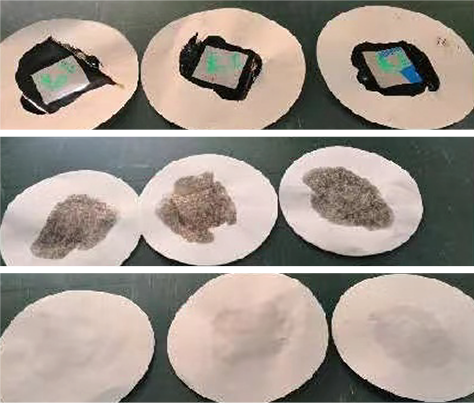

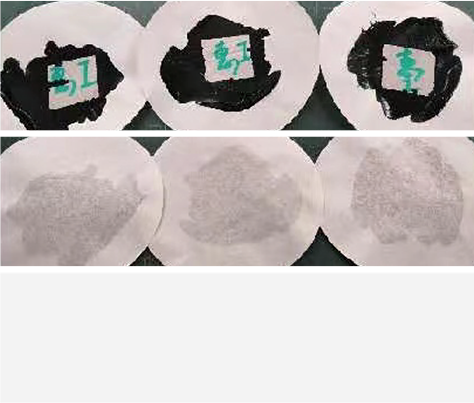

90% CNOOC 90 #+10% Hualinruisi resin

50% 70 #+50% silicone asphalt

66.7% 70 #+33.3 silicone asphalt

4,5,5 (number of oil seepage sheets)

1,1,1 (number of oil seepage sheets)

1,1,1 (number of oil seepage sheets)

High modulus modified asphalt mixture generally refers to special mixtures with higher modulus than modified asphalt mixture. Currently, high modulus asphalt mixture mainly involves adding high modulus agents during the mixing process to improve the modulus of asphalt mixture

After years of technology and research and development, National Innovation Materials has developed a high modulus asphalt mixture additive based on silicone modified asphalt, which is suitable for heavy-duty traffic, high-temperature areas, long longitudinal slopes, and airport road surfaces. It not only significantly improves the dynamic modulus and high-temperature stability of asphalt mixtures, but also mainly solves the problem of insufficient pavement strength And road surface problems such as rutting and deformation caused by poor high-temperature performance of asphalt mixtures

根据PG分级检测结果,SMA改性沥青适应的温度

Pilot projects | temperature | Experimental indicators | Experimental values | technical requirement | pass through(P) NO PASS(F) | test method | |

Original asphalt | viscosity | 135℃ | Viscosity(Pa.s) | 2.9 | ≤3.0 | P | T0625-2011 |

Dynamic shear rheology DSR | 82℃ | G*/sinδ(kPa) | 1.1242 | G*/sinδ≥1.0 | P | ||

88℃ | G*/sinδ(kPa) | 0.5407 | F | ||||

G*/sinδ=1.0The temperature is:83.2℃ | T315-10 | ||||||

RTFOT residual asphalt | Dynamic shear rheology DSR | 82℃ | G*/sinδ(kPa) | 3.29 | G*/sinδ≥2.2 | P | |

88℃ | G*/sinδ(kPa) | 1.93 | F | ||||

G*/sinδ=2.2The temperature is:86.8℃ | T313-10 | ||||||

PAV后 residual asphalt | Curved beam BBR | -12℃ | Creep strength S(MPa) | 256 | S≤300 m≥0.300 | F | |

m值 | 0.259 | ||||||

-6℃ | Creep strength S(MPa) | 130 | P | ||||

m值 | 0.366 | ||||||

m=0.3critical temperature:-11.6℃,此时S≤300 | T315-10 | ||||||

dynamic shear DSR | 30℃ | G* | 4208 | G*/sinδ ≤5000 | P | ||

27℃ | (kPa) | 6232 | F | ||||

| Serial number | Sample name | Ingredient name | content | notes |

| 1 | Component name SMA asphalt modifier Black powder | PP. % | 2.5-3.0 | / |

PP. % | 2.0-2.5 | / | ||

notes | / | |||

| Serial number | Sample name | Ingredients | content | notes |

| 1 | SMA asphalt modifier Black powder | C5,% | 6.0-6.5 | / |

notes | / | |||

Copyright © 2012-2022 Copyright Qingdao Guochuang New Material Technology Co., Ltd 鲁ICP备2023012903号